Ultrascan 70 at CREST National |

This article first appeared in |

| Written by: Jon R Truckenmiller, Sr. VP, Engineering. Letter to to Mr. Ole Alstrup dated February 12, 1993 |

Issue 65 - July 2001 Updated: 18.03.2023 |

|

|

More in 70mm reading: |

|

Ultrascan 70 saw first commercial transfer elements in March 1991. The first

feature transfer was

"2OO1: A Space Odyssey" and was mastered direct from a 65mm printing

negative number 1, dated 1968, for Turner/MGM/UA. The next restoration

projects tackled included non-linear anamorphic, unsqueezed from Ultra

Panavision print elements of

"It's a Mad, Mad, Mad, Mad

World" and

“The Hallelujah Trail”. This same process was used in the

restoration of "The

Alamo". Universal Studios utilized their 65mm inter positive, made

optically from the 35mm Technirama negative, for the supervisor transfer of

"Spartacus".

Transfer of MGM/UA's "West

Side Story" was made from a 65mm laboratory inter positive and was

supervised by the director Robert Wise. Perhaps the most challenging transfer to date was the restoration of "Chitty Chitty Bang Bang". Shot in 1968 utilizing the wide screen photographic process, Super Panavision, a 65mm color original negative had been created and Technicolor had been selected as the motion picture laboratory to be used for processing, answer print and release print production. The 65mm camera original was conformed for printing on Technicolor's Auto Select, 65mm printer. The limited number of 70mm release prints required were generated by this printer, direct to 70mm print stock. A reduction 35mm CRI was created and used for general 35mm cinema release printing. No laboratory 65mm intermediate elements were created. One of the many unique features of Auto select printing, is the ability to avoid frame line splices showing in the full frame, 5 perforation, wide screen exhibition format. To achieve this task the printer, from paper cue tapes, physically skips 2 frames at every splice. In doing so it creates a clean scene transition, but requires the conformed film to have an extra two frames offset built it for each scene or splice of the feature. For conventional laboratory printing, camera original negative is conformed into an "A" roll and separate "B" roll. Each roll is checkerboarded back and forth and when a dissolve is desired an overlap of scenes is built into the respective rolls. Fader cues are used to determine fade ins and fade outs. Each roll is printed as a separate pass onto the raw stock, creating a dissolve during the overlap phase. Auto-select printing differs from these normal laboratory procedures by utilizing an A roll only. Auto-select creates all fades and dissolves at print time from the one roll of specially conformed camera original. The Auto-select printer in operation closes it's fader, backs up the raw stock, advances the original, then opens the fader while printing, to complete the transition. The single A roll contains all scenes, and material for fades and dissolves. The previous film to video transfer of this feature had been performed in October 1981. The pan and scan from a 35mm release print was found to be lacking by today digital standards for release to Video Laserdisc, and was not in the letterbox wide screen format. It was found that no 70mm release prints containing little damage or age deterioration existed, and since no laboratory intermediate existed it was deemed appropriate to use the original camera negative for this transfer. The large format negative, mounted as 1AB - 9AB was shipped from the Hutchinson, Kansas salt mine storage repository, and on arrival inspected and determined to be in excellent condition. Laboratory records showed last physical activity for this element to have been in 1978. Color grading proceeded as normal, with the exception of the complexity of the Auto-select, conformed negative, with its slugs and undocumented cues. Imagine what happens as scene changes occur and the sound track sync moves progressively two more frames delayed. Software on Crest's telecine control system was modified to allow for an Auto-Assemble of the entire feature: a process in which, at every scene change the digital recorder and the telecine would stop, mark, back cue and roll. In this process, the transfer was completed with 2,789 I/C transitions. Extensive use was made of read-before write edits to create all fades and dissolves required throughout the feature allowing for true first generation quality. And if this was not enough, it was found that in the 1981 transfer, or at some other undocumented time, the Intermission was moved and footage in the 65mm version deleted and changed. The 1992 restoration transfer was corrected to fully replicate the 1968 theatrical road show release version of this feature. |

|

|

Ultrascan 70 today is being utilized not only for these restoration projects on theatrical productions, but has to date, logged over 1.000.000 feet of "dailies" production. 65mm camera original direct from laboratory process is mastered, logged and dubbed for delivery worldwide. As an example, the production "Concerto for the Earth" was shot during the autumn of 1991 through spring 1992 on location in 13 countries, spanning the globe, for display in the Environmental Pavillion at EXPO 92, Seville, Spain. This project was the first production to utilize Showscan Productions new wide screen 3D photographic process. Showscan employs a two camera 65mm rig delivering a left eye 65mm negative and a right eye 65mm negative, with an aspect ratio of 2,2:1 and a projection rate of 60 frames pr. second. The production company realized that the cost of print-down (65-35) work picture for the anticipated thousands of feet required and the need for some form of verification that the material being shot, in some of the most remote areas of the world, was acceptable. They demanded an alternative solution. Using Ultrascan 70 and our Express 65 Video dailies allowed the production company to air freight exposed film to Los Angeles, and on completion of processing create a direct transfer from the OCN, including the Eastman 65mm key kode data for later conforming edited video to 65mm film. This same video daily in cassette form would be air freighted out to location for viewing and evaluation. This process, with flight travel time, turned out to be about a four day step, beating the conventional film turnaround by almost two weeks. Imagine screening dailies in video form, with a generator-powered monitor in the grass out in the Serengeti, nearest telephone 390 miles. Finally you enquire as to the URSA and 70mm transfers. If I had felt an URSA would have provided a technical improvement in quality or in ease of creation, such a system would have been used. The only benefit from URSA would have been in the area of rotation of horizontal format images, (VistaVision or IMAX type 15 perf) however, both of these formats present challenges to any system. We have experimented in the field of VistaVision, but the market is actually very small and material in archive in this format is usually in three strip (YCM) masters, requiring pin registration and composite imaging. This is not a cost effective form of transfer. In rotation transfers, as the flying spot scanning system is a real time continuous motion system, the actual image in the scanning gate must be about 2x frames in size to "see" the entire frame. For Ultrascan 70, I have established a daily type work around system for 15 perf transfers that we currently use. However, the design drawings and specifications for a gate spanning the 30 perfs required for true 15 perf full resolution scanning would create a device that is physically larger than the deck plate of Rank, and the cost of flawless optics for negative transfer is equal to the price of a new URSA. Once again the dream continues. |

|

70mm Films in Ultrascan 70 (List incomplete) |

|

|

2001:A Space Odyssey The Hallelujah Trail South Pacific Oklahoma! STAR! It's a Mad, Mad, Mad, Mad World The Alamo Spartacus West Side Story Chitty Chitty Bang Bang The Sound of Music Baraka |

|

Crest National |

|

|

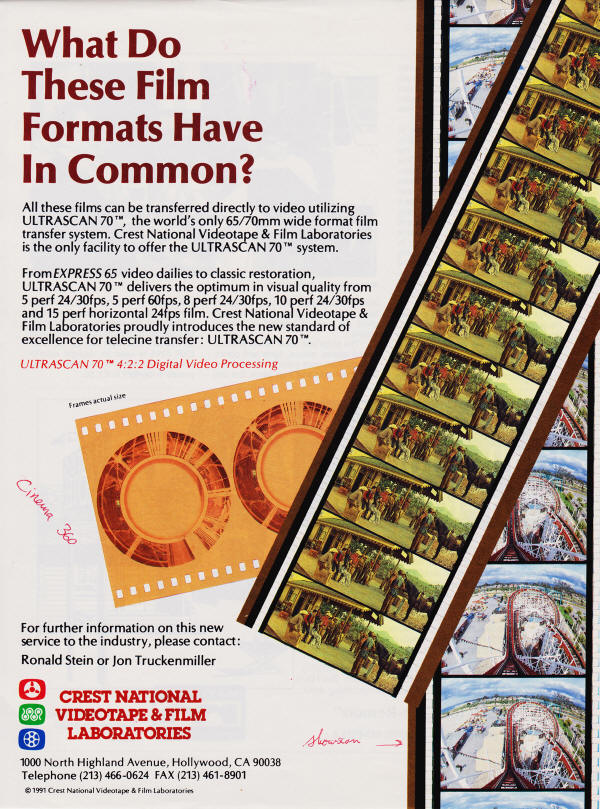

Crest National, in Los Angeles, has the capability to large format film directly to videotape using a specially modified Digital Rank. The Rank masters 65/70mm 5, 8, 10, or 15 perf film from original negative,

I.P., I.N., or print to all tape formats. Letterbox and pan & scan can be

accommodated. |

|

| Go: back

- top - back issues Updated 22-01-25 |