Restoring Cinemascope 55

|

Read more

at in70mm.com The 70mm Newsletter |

| Written by: Cineric, provided by Schawn Belston, 20th Century Fox | Date: 8 March 2005 |

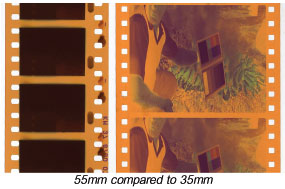

55mm compared to 35mm 55mm compared to 35mmCinemaScope 55 is a format 20th Century Fox introduced in 1956 to address the problem of the poor resolution of the current camera stocks of the time. Their engineer’s solution was to use more image area and the format they decided on was a negative that is 55.625mm wide by eight perforations high with foxhole perforations. The camera aperture is 1.824 in by 1.430 in and the image has a 2:1 anamorphic squeeze. This means Cinemascope 55 has the same aspect ratio as 35mm Cinemascope(2.55) but 3.8 time the image area. Two features and a short were shot in this format and then the process was abandon for the 65mm 5 perf non anamorphic system chiefly because of the drawbacks of the anamorphic optics of the time. There were experiments made with 55mm release prints but this idea was abandoned also. Instead, 35mm Cinemascope 2.55 reduction prints were made for exhibition. All this leads to the currant problem Fox has of two features that are an important part of their library in a film format that is obsolete and te only film element existing in 35mm is an interpositve made in the 60’s of inferior quality. |

Further

in 70mm reading: Magnified Grandeur In The Splendour of 70mm Film "Carousel" screening CinemaScope 55 CinemaScope 55 |

Bell & Howell Foxhole Bell & Howell FoxholeCineric faced many technical and logistic challenges in the restoration of the two 55mm features so we will break them down individually and illustrate our solutions. |

|

55mm liquid gate 55mm liquid gateThe first challenge was physically transporting the film in order to re-photograph it. The original optical printer gates are still in existence but worthless for our purposes because they were designed for brand new un-shrunken film. The original negative and the 55mm separation masters exhibit shrinkages from 0.5% to 0.7 % and any attempt to run the film through to old gates would shred the perforations. The other problem with the old gates is that they are dry gates. The original negative has been heavily handled and mishandled over the years so liquid gate printing is necessary to hide the many surface defects. Because of these issues we had to start from scratch. Cineric’s machinist modified the design of a PES liquid gate to accommodate the wide gauge and height of the 55mm frame and made a custom set of registration pins to fit the dimensions of the shrunken Foxhole perfs of the film we were working with. The bevel of the pins was increased from normal to gently guide the pin into damaged perfs and to deal with out of pitch splices. The guide pin was also undersized laterally to film to deal with the varying shrinkages. The stroke of the gate was made adjustable from 0% shrinkage to 50% shrinkage. This allowed us to precisely adjust the gate on a roll-by-roll to the film when necessary. Our optical printers are designed to advance film four perforations at a time so to get around this we set a sequencer on the printer to photograph every other advance of the projector to get the full 8 perf movement. In addition to the gate we had to manufacture sprockets, rollers, synchronizers, split reels, cores and rebuild a cleaning machine to fit the film. |

|

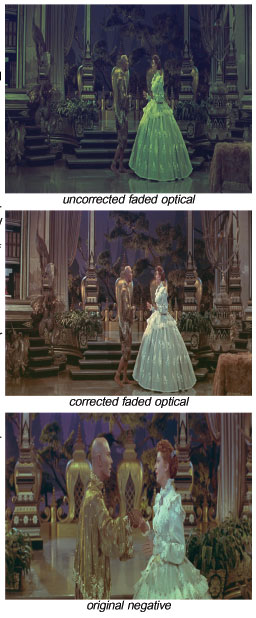

Uncorrected faded optical Uncorrected faded opticalCorrected faded optical Original negative The next problem we had to address was rips, slugs and faded opticals in the original negative. There were 55mm separation masters made and the provided valuable replacement sections for the films but unfortunately they where missing a considerable amount of footage. For one film the separations were made before a few of the opticals were replaced and then cut down to make a shorter version of the film. For the other title the masters were make before any of the opticals or titles were cut in and were missing some additional scenes. For the scenes where we did use the separation masters, the process differed little from the one we would use for standard 35mm masters.We ran the separations through the printer twice. The first time we only shot seven frames from each scene at a best guess light to produce a condensed internegtive of the film. This internegative was fully answer printed and this timing was used to make a full length timed out internagtive from the masters. Any registration problem due to differential shrinkage in the masters was corrected reel by reel by repositioning the lens with stepper motors. The sections that were faded or damaged that had no masters we scanned at 4k on an Oxberry scanner, corrected the curves and damage and recorded out a 35mm negative at 4k to use as a b-roll to the original along with the negative sections from the masters. Despite the 3.8 time image area, the 55mm negative has the grain structure of a contemporary 35mm scope negative shot on 500asa 5279. Through tests scanning at different resolutions we determined that 3k resolved the grain clearly and 4k gave us some safety room. The opticals in both films were suffering about 50% dye fading in the yellow and 25% in the cyan. |

|

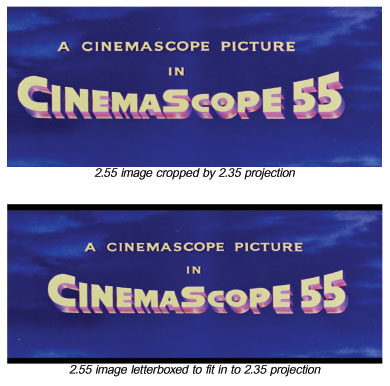

2.55 image cropped by 2.35 projection 2.55 image letterboxed to fit in to

2.35 projection 2.55 image cropped by 2.35 projection 2.55 image letterboxed to fit in to

2.35 projectionOnce the b-rolls were assembled, they were fully answer printed with the 55mm original negative. Once the timing was approved a full aperture 2.55 35mm wet gate optical interpositive was manufactured. This led to the last interesting issue of this restoration. There are very few facilities in the world that can project a full 2.55 image and since the image extends halfway into the track area, the only practical way to run sound with the print is interlocked mag tracks. These limitations severely limit the chances of the film being shown so another solution was needed. The final decision was to make a internegative on an optical printer reducing the image into a standard scope aperture. The projected image has the full 2.55 aspect with slight black panels on the top and bottom in standard projection and has room for a contemporary analogue and digital track. |

|

| Go: back

- top -

back issues

- news index Updated 22-01-25 |

|