Designing Logmar's ultra-light Magellan 65 Camera |

Read more at in70mm.com The 70mm Newsletter |

| Interviewed & Photographed by: Thomas Hauerslev, in70mm.com | Date: 07.05.2018 |

Tommy, please tell me about your background as a camera engineer Tommy, please tell me about your background as a camera engineerI am not actually a camera engineer but rather educated as a mechanical designer and have always had a passion for cameras. I bought my first Super 8 camera when I was 10 years old (1960) and I have filmed ever since. Of course, not continuously, because as you know, when the kids were small, the camera went into the closet. Back in 2012 I started investigating the idea of perfecting Super 8 and had some good ideas about 16mm as well, so I started started dedicating much time in this direction. I started these projects when I was still employed at Martin Professional in Denmark and at some point, I had to quit my job, because the Super 8 project took all my time. What inspired you to build a new 65mm camera? It was actually my son who jokingly said "Why make a Super 8, when we can make a 65?"? You know, "Size matters" [Laughing]. During my travels, I asked around in the business, and several people told me "There is no business in 65, don't start with that". But, never say "don't" to me [laughing]. When I returned, I started thinking about a 65mm camera and have done so ever since. The 65mm was developed side by side with the Super 8 in principle, however, the Super 8 took so much of the time, so I only worked on the 65mm in my spare time. It wasn't until we finished the contract with a third party for an 8mm camera that I started to develop it on my computer in 3D. • Go to Gallery: The Magellan 65 Camera • Go to Gallery: Behind the scenes with Tommy Madsen, CEO Logmar • Go to Logmar Camera Solutions premieres a new hand-held 65mm Camera What is the basic idea and design considerations of the new Magellan 65mm camera? Light weight and as small as possible of course. That was our goal from the very beginning. If we were to make a 65mm camera, it should not be a big and bulky apparatus. It should be possible to carry it on your shoulder, and be as small as possible. |

More in 70mm reading: Magellan 65 Presented in Hollywood Gallery: The Magellan 65 Camera Gallery: Behind the scenes with Tommy Madsen, CEO Logmar Logmar Camera Solutions premieres a new hand-held 65mm Camera The Importance of Panavision A New 65mm Film Camera MCS 70 Field Camera The Making of ARRI 765 Todd-AO AP65 65mm camera Todd-AO Equipment Catalog Internet link: Logmar Camera Solutions IVS Silovej 8, 2. DK-9900 Frederikshavn Denmark +45 93 98 08 50 Tommy Madsen - Chief Executive Officer. Logmar Camera Solutions, Denmark logmar.dk |

How about the noise level on this camera, was that a design

consideration? How about the noise level on this camera, was that a design

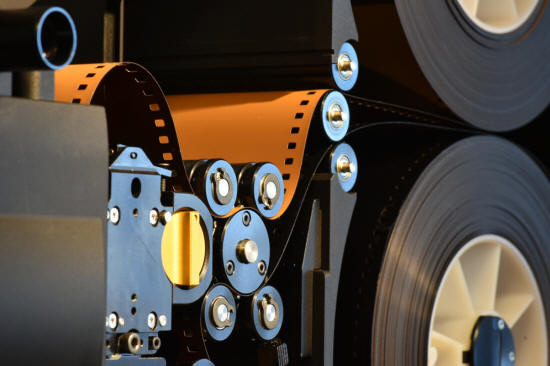

consideration?Yes, but it is very, very, difficult with such a wide film, as all the mechanics are much bigger compared to the Super 8 camera. What makes the noise in a camera? Normally the gears, but in this camera, there are no gears, only belts, and belts don't make noise as such. The registration with the two claws and the pins, that are also belt driven and all the rotating metal parts (and film loops) all generate noise, so you can't eliminate it totally, even though we have invested a huge effort into in-camera insulation whereever possible. What is the major difference between your camera and cameras already in the market? The main difference is we are using an oscillating mirror (or guillotine) shutter instead of a rotating disc mirror in a 45 degree angle which “everyone else” is using. If I had chosen the rotating disc, the camera would be wider and longer. So essentially, we took the basic idea of the Logmar Chatham S8, and just made it bigger. We know our Super 8 camera works extremely well, so we thought, why change it, if we could use the same concept with 65mm? What else is new in this camera compared to other cameras? The electronic view finder is new. I know many cinematographers will say "You can't have a camera with an electronic viewfinder". I think time will show that you can, because it is much easier to operate. All digital cameras have electronic viewfinders, and they work very well, so of course it can work on a film camera as well. The misconception is that the electronic-View Finder (eVF) in a film camera looks straight out of the lens but that’s not the case at all. Our eVF looks at a ground glass exactly as if you were looking at it in an optical viewfinder. With the resolution of either Full HD or 4K Ultra HD, people will be able to see much better what is going on in a low light scenario than they would with an equivalent optical view finder. The eVF when combined with our 2.4GHz and 5GHz Wi-Fi also allows remote viewing when the camera is used on a crane or similar – again something an optical viewfinder wouldn’t be good at. How many years of research and development went into presenting this prototype? We spent seven months designing the blueprints and making CAD and then another 14 months having it manufactured, but I will say that we spent the better part of two quarters of a year doing nothing because our metal vendors were a bit slow. |

|

What were the major problems during development? What were the major problems during development?I don't see them as problems, more like challenges. The exterior has changed a little during the process as I mentioned, but I always had the same plans for the inside of the mechanism. When you build a camera and you follow your instinct and your own ideas, then when you assemble the parts as they arrive, then of course, some changes pop up. Always. It's impossible to make a drawing, order the parts, put it together, and make it work 100% the first time. There is no way that will happen How did you learn how to draw in a computer? I don't know, I just do it [laughing]. I am not a skilled computer user at all being 68 years old and when I was designing in my earlier jobs I always drew by hand and had colleagues make the CAD from it. The trouble was, though, that when I started Logmar I didn’t have any colleagues so before I could build my first camera, I had to learn how to use a CAD program, because I didn't know. That was great motivation and luckily my son had a friend who taught 3D CAD lessons in evening school so I asked him some questions about it, and after 10 questions, I said "I think I can do it" and here we are today [smiling], and I could, because I just need to learn how to start. And then everything just followed. When you use it every day, you just learn more and more. The software can do so many things, and I may have only used on tenth of what it can do, but it is enough to build a camera. Our first investment was a 3D printer, and that was a good idea for the prototype, because you can see if things fit all the right places. All the threads etc., and when you are sure everything works, you send the files to the machine shop. We use one company in Copenhagen, which are also making parts for the Phase One camera, and another other vendor in Sønderborg. We found them on the internet. At first I mailed them, followed by phone calls, and finally I visited them in person. The Copenhagen vendor made all the parts for the Super 8, but they could not manage to make all the parts for the 65, so we had to find an extra supplier. They did everything from the camera body, magazines and everything. Screws, belts and gears is something you can buy on the internet. It's the same with the Super 8. Despite the fact we do have a nice office facility, both cameras are mainly designed and the first prototypes are build in my kitchen because I like sitting in my home doing this work where there are no distractions and phones ringing. |

|

How many cameras will be available? How many cameras will be available?We have 15 cameras available and can manufacture more with approx. 8 months lead time. Will the new cameras be for hire, or purchase? We have not yet decided upon a business model for the Magellan camera. What's the price of a 65mm camera? TBD. What kind of service will be available for the new camera? We will offer a long term service program, and depending on the business model we choose, potentially train external partners on the servicing also. Tell me about the design consideration of using Carl Zeiss's Hasselblad lenses We thought Carl Zeiss is a very good brand and well known. When you put a lens in front of a 65mm film, the lens should cover the whole area, and we found out that Hasselblad lenses are perfect for that job. That's why we chose the Hasselblad lenses which are also the same types ArriFlex used for their 765 camera just slightly modified. Actually the Bronica was my first thought but Zeiss lenses just had a better brand name so they got chosen in the end and Zeiss lenses are also used for IMAX films, and will do the job on the Magellan. Finally there are a lot of these lenses available and Carl Zeiss is still offering collimation and service on them. |

|

Do the lenses need to be rebuilt to be able to use them on a film camera? Do the lenses need to be rebuilt to be able to use them on a film camera?No, but the only thing you need to do is to check that they are collimated, which means they are sharp at infinity. How do you control focus on the lenses? Focus is done manually, but you can get some plastic gears you can mount on the lenses with a little motor to remote control focus. Usually, this equipment belongs to the focus puller, who mounts this on the lenses. Is it possible to use Panavision or ARRI lenses on the Magellan? Only if we change the mount on the camera. If someone want to use these lenses, we can get these mounts manufactured. Can the Magellan run upside down? I think it can, we haven't tested it like that currently though. How is time code applied? There is a Kodak key code on the film which tells what frame you’re currently on and when you slate the film you can note the frame number from the viewfinder menu and thereby get an offset to “reality” against the key code. The camera itself does not record time code because it doesn’t need to as it runs in sync. |

|

The quality of the electronic viewfinder, is that good enough to cut into

the film? The quality of the electronic viewfinder, is that good enough to cut into

the film?No, because it is an image off the ground glass, and that is how we made our digital viewfinder. In a digital camera you take the signal from the actual sensor which "looks" through the lens and apply the “ground glass” effect in post processing, but in the Magellan viewfinder, you see the actual high-resolution ground glass and then we overlay the frame guide and digital information on top. It is very useful for the people on the set to have the picture from the viewfinder with these lines. For instance, the boom operator can see his boom outside the frame. How is the camera controlled? There is a small display on the right side of the Magellan with six buttons. We have discovered it is a little difficult to operate given its size so we will be replacing it soon with a much larger screen. The Magellan is equipped with a very powerful quad core computer from NVIDIA which controls all aspects, including the Sony Full HD or 4K UHD eVF. The eVF sensor is the most effective low-light sensor available from Sony which enables you to operate the camera even at night. Imagine that with an older optical view finder? You wouldn’t be able to see a thing because it is so dark. On the Magellan, however, you can see everything. What are your expectations for the premiere at the CineGear expo? I hope a lot of visitors will come and see us, and we will be able to give them value for their money. We can only answer questions, but people can get a look-and-feel impression of the camera. They can lift it and see how it looks. We will not be running film during the expo as we are still fine tuning the drive train but we should have trial footage up on our website by mid-July. |

|

What kind of interest have you met from the industry? What kind of interest have you met from the industry?There has been a tremendous interest during this week of launch since the introduction on April 30. The whole world is "buzzing" with interest and we have gotten a lot of meeting proposals by phone from respected companies and individuals while also having received loads of e-mails from nearly all over the world, and we already sent out material and interview to a Japanese and German magazine, and I think there will be more. Please remember, it's only been announced for a week. I think after two weeks, everything will be "boiling" if this pace keeps up. Why should film makers use the Magellan on a film production? I think it could be used especially for hand-held shots, and of course on a tripod as well. You can say, it is handier than most current 65mm cameras out there right now. You should use the Magellan to make many new interesting and creative shots, because it is a very compact camera. With the viewfinder feed, you can control the camera remotely, and control it with your cell phone or tablet with the built in Wi-Fi and Bluetooth. How about using it on your skateboard? Hold it in your hand, and look at a monitor mounted on the camera instead of staring down a viewfinder tube like on other cameras which would be difficult to do with an optical viewfinder. With a wide angle, you have no idea what you are photographing, because you cannot see it. You do it blind. But you can see everything with the Magellan 65. You can do new things with our camera which previously were impossible, or very complicated, simply because the cameras were too big and too heavy. We feel the Magellan 65 will bring new things for storytelling into large format films. |

|

| Go: back - top - back issues - news index Updated 22-01-25 |