Todd-AO Equipment Catalog, Volume IV |

Read more at in70mm.com The 70mm Newsletter |

| Captions by: Brian O'Brien, Jr. around 1955. Images by: American Optical Company, around 1955. | Date: 21.05.2014 |

Fig. A-294.

Todd-AO Variable Speed Motor shown without motor door mounting plate. Fig. A-294.

Todd-AO Variable Speed Motor shown without motor door mounting plate.Todd-AO Variable Speed Motor (Cat. #10) Todd-AO Camera Motors The Todd-AO Camera Motors are of two types: the Variable Speed or "wild" motor and the High Torque Synchronous Motors. The Variable Speed Camera Motor operates on 110 volts either 60-cycle alternating current or direct current and permits running the camera either forward or reverse at speeds varying from about 8 frames per second up to 32 frames per second. The Todd-AO High Torque Synchronous Motor is specially designed for the Todd-AO Cameras to pull the heavier 65mm film. It is a salient pole synchronous motor operating on 230 volts, 3-phase alternating current. This motor has an integral sound-proof outer housing and runs very quietly. |

More in 70mm reading: Back to Todd-AO Catalog • Todd-AO Birth date • How Todd-AO Began • Todd-AO Home • DP70 / Universal 70-35 / Norelco AAII - The Todd-AO Projector Internet link: |

Fig. A-293.

Operator's view of the Todd-AO Variable Speed Motor showing camera speed

tachometer. The machined boss on the left is for locating motor onto the

motor door adapting plate with its couplings. Fig. A-293.

Operator's view of the Todd-AO Variable Speed Motor showing camera speed

tachometer. The machined boss on the left is for locating motor onto the

motor door adapting plate with its couplings.Todd-AO Variable Speed Motor (Cat. #10) In order to prevent the high starting torque of the Synchronous Motor from damaging the film, the Soft Start Motor Control Box has been developed. This contains a clock driven timing relay that applies reduced voltage to the motor in two steps and then applies the full line voltage. Thus, the motor starts with a low torque which softly takes up the slack film before the full power is applied. This is completely automatic so that the operative cameraman need do no more than operate a conventional camera cord switch and in approximately three seconds the camera is up to speed. A neon pilot light shows when the line is energized. This Soft Start Control Box may be inserted at any convenient place in the camera power line. |

|

Fig. A-350.

Todd-AO Variable Speed Motor showing the manual camera threading knob. The

knurled disc at the bottom of the motor is the speed control adjustment. Fig. A-350.

Todd-AO Variable Speed Motor showing the manual camera threading knob. The

knurled disc at the bottom of the motor is the speed control adjustment.Todd-AO Variable Speed Motor (Cat. #10) When used in conjunction with the Camera Frequency Converter, the Todd-AO High Torque Synchronous Motors will operate the Todd-AO Cameras at a speed of 24 frames per second instead of the Todd-AO standard speed of 30 frames per second. The Frequency Converter supplies 48 cycle, 3-phase alternating current so that by merely throwing a switch, a 24-frame retake may be made without any change in setup and without losing any time. Such 24-frame retakes are made on those scenes which cannot be speed reduced from 30 to 24 frames in the Print Down process for residuals. |

|

Fig. A-349.

Operator's side of the Todd-AO Variable Speed Motor attached to the Camera

Adaptor Door. Fig. A-349.

Operator's side of the Todd-AO Variable Speed Motor attached to the Camera

Adaptor Door.The combination cable set shown connects the camera to the power line through the buckle trip switch which is mounted in the Adaptor Door. Todd-AO Variable Speed Motor (Cat. #10) Camera Adaptor Door (Cat. #09) |

|

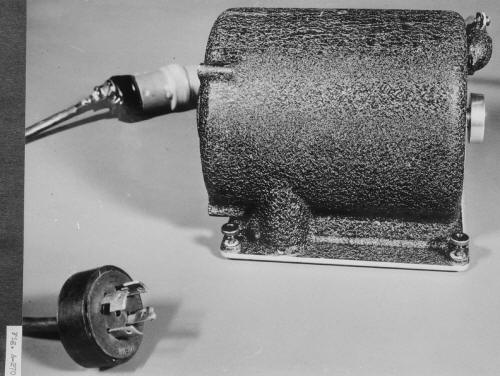

Fig. A-270.

Todd-AO High Torque Synchronous Camera Motor. It operates on 230 volt,

3-phase alternating current. Fig. A-270.

Todd-AO High Torque Synchronous Camera Motor. It operates on 230 volt,

3-phase alternating current.Todd-AO High Torque Synchronous Camera Motor (Cat. #08) |

|

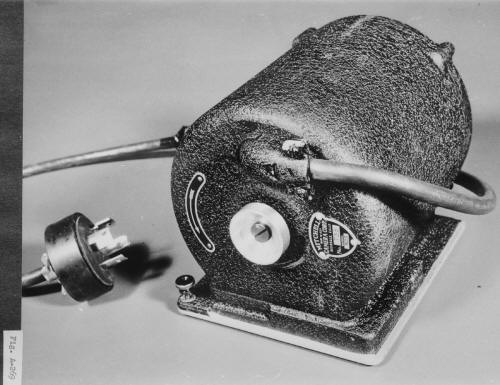

Fig. A-269.

Rear view of the Todd-AO High Torque Synchronous Camera Motor. Fig. A-269.

Rear view of the Todd-AO High Torque Synchronous Camera Motor.Todd-AO High Torque Synchronous Camera Motor (Cat. #08) |

|

Fig. A-389.

The Todd-AO Soft Start Camera Motor Control Box. Fig. A-389.

The Todd-AO Soft Start Camera Motor Control Box.Todd-AO Soft Start Camera Motor Control Box (Cat. #30) |

|

Fig. A-388.

The Todd-AO Soft Start Camera Motor Control Box showing the camera cable and

simple operator's on-off cord switch. Fig. A-388.

The Todd-AO Soft Start Camera Motor Control Box showing the camera cable and

simple operator's on-off cord switch.Todd-AO Soft Start Camera Motor Control Box (Cat. #30) |

|

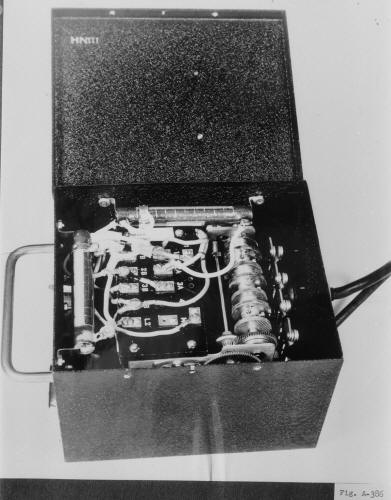

Fig. A-386.

Interior view of the Todd-AO Soft Start Camera Motor Control Box showing the

positive action mechanism. This Control Box will operate in any position.

Large, self-wiping silver contacts, shown at the right are operated from the

adjustable cams on the timing shaft. A soft humming noise is produced by the

unit until the camera is up to speed, at which time this tone stops

automatically giving the operator an indication that his camera is at speed. Fig. A-386.

Interior view of the Todd-AO Soft Start Camera Motor Control Box showing the

positive action mechanism. This Control Box will operate in any position.

Large, self-wiping silver contacts, shown at the right are operated from the

adjustable cams on the timing shaft. A soft humming noise is produced by the

unit until the camera is up to speed, at which time this tone stops

automatically giving the operator an indication that his camera is at speed.Todd-AO Soft Start Camera Motor Control Box (Cat. #30) |

|

Todd-AO Hydraulic Camera Tripod |

|

Fig. A-212.

Todd-AO Hydraulic Camera Tripod shown in its lowest position and with its

clamping jacks retracted for moving. Fig. A-212.

Todd-AO Hydraulic Camera Tripod shown in its lowest position and with its

clamping jacks retracted for moving.Todd-AO Hydraulic Camera Tripod (Cat. #23) The Todd-AO Hydraulic Camera Tripod provides an exceptionally stable platform for the Todd-AO Cameras while being instantly adjustable for height and level anywhere from 21 inches to 60 inches above the ground. Dynamic analysis of existing units on the market showed several very basic weaknesses, among which was a great lack of torsional stiffness, which permitted the camera to shake or twist even in a slight wind. The Todd-AO Modifications provide stiffness in the tripod legs at the top where it is needed, and the specially designed wide base clamp block assembly at the top of each leg permits a quarter turn of the locking lever to firmly secure the tripod in position. |

|

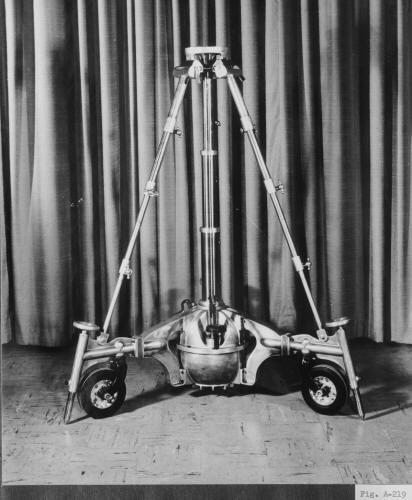

Fig. A-219.

Todd-AO Hydraulic Camera Tripod shown in its fully extended position with

the three clamping jacks lowered, taking the weight off the wheels. Fig. A-219.

Todd-AO Hydraulic Camera Tripod shown in its fully extended position with

the three clamping jacks lowered, taking the weight off the wheels.Todd-AO Hydraulic Camera Tripod (Cat. #23) The machining tolerances have been held so closely that even without tightening the clamping blocks there is only barely perceptible rotation of the tripod head. Full-caster rubber-tired wheels permit easily moving the tripod with the camera in place, and three clamping jacks then screw down, firmly anchoring the unit. |

|

Fig. A-216.

Close-up of the top of the Todd-AO Hydraulic Camera Tripod showing the

clamping blocks at the head of each leg strut. Fig. A-216.

Close-up of the top of the Todd-AO Hydraulic Camera Tripod showing the

clamping blocks at the head of each leg strut. |

|

Fig. A-214.

Close-up of the head casting of the Todd-AO Hydraulic Camera Tripod. Two of

the head clamping blocks are in place and the third has been removed to show

the machined surfaces of the clamping block bosses. Fig. A-214.

Close-up of the head casting of the Todd-AO Hydraulic Camera Tripod. Two of

the head clamping blocks are in place and the third has been removed to show

the machined surfaces of the clamping block bosses.Todd-AO Hydraulic Camera Tripod (Cat. #23) |

|

Fig. A-208.

Hydraulic tripod leg strut before being modified. Notice that the right-hand

end is the small diameter end and this was at the top of the strut. Fig. A-208.

Hydraulic tripod leg strut before being modified. Notice that the right-hand

end is the small diameter end and this was at the top of the strut. |

|

Fig. A-222.

Todd-AO Hydraulic Camera Tripod leg strut.

Note the wide top trunnion and the large diameter top section of the

telescoping strut. Fig. A-222.

Todd-AO Hydraulic Camera Tripod leg strut.

Note the wide top trunnion and the large diameter top section of the

telescoping strut.Todd-AO Hydraulic Camera Tripod (Cat. #23) |

|

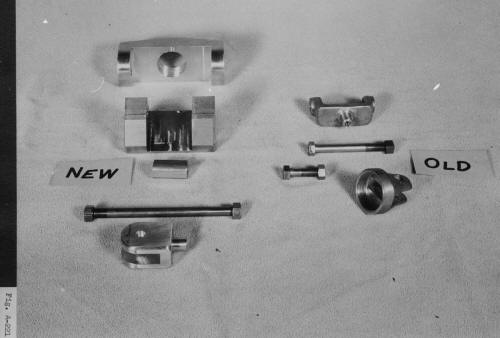

Fig. A-221.

Comparison of the leg strut assembly in exploded view of the Todd-AO

Hydraulic Camera Tripod and the old, simple cast trunnion which it replaces.

Note the clamp and spacer cylinder construction which permits rigid

tightening of the locking bolt without springing of the clamping bosses on

the head casting. Fig. A-221.

Comparison of the leg strut assembly in exploded view of the Todd-AO

Hydraulic Camera Tripod and the old, simple cast trunnion which it replaces.

Note the clamp and spacer cylinder construction which permits rigid

tightening of the locking bolt without springing of the clamping bosses on

the head casting.Todd-AO Hydraulic Camera Tripod (Cat. #23) |

|

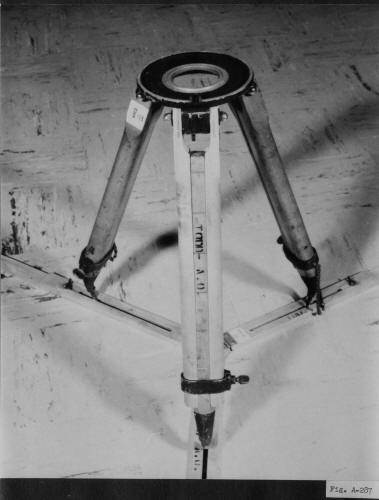

Fig. A-291.

Standard Mitchell tripod shown mounted on a leg spider or tripod banjo which

prevents slipping. Fig. A-291.

Standard Mitchell tripod shown mounted on a leg spider or tripod banjo which

prevents slipping.Standard Mitchell Tripod (Cat. #25) |

|

Fig. A-287.

Standard Mitchell Baby Tripod shown mounted on a leg spider or banjo. Fig. A-287.

Standard Mitchell Baby Tripod shown mounted on a leg spider or banjo.Standard Mitchell Baby Tripod (Cat. #26) |

|

Fig. A-292.

Standard Mitchell High Hat shown placed on a tripod banjo only for

comparison. The High Hat is a one-piece casting. Fig. A-292.

Standard Mitchell High Hat shown placed on a tripod banjo only for

comparison. The High Hat is a one-piece casting.Standard Mitchell High Hat (Cat. #27) |

|

| Go: back - top - back issues - news index Updated 28-07-24 |