Todd-AO Distortion Correcting Printing Process |

This article first appeared in |

| Written by: Grant Lobban, England | Issue 42 - December 1995 |

|

|

Further

in 70mm

reading: |

Distorted

Screen Image.

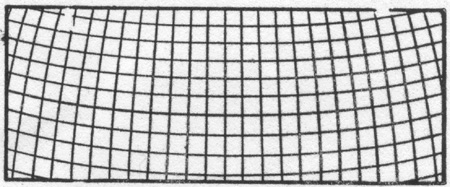

The drawing shows how straight horizontal and vertical

lines are distorted by keystone and screen curvature. Distorted

Screen Image.

The drawing shows how straight horizontal and vertical

lines are distorted by keystone and screen curvature.Two classes of print were to be produced, one to cover projection angles from 10 to 15 degrees and another for even higher angles. In theory, it was an workable idea, but each type of print was required to cover a range of circumstances. For a perfect system, it would really need to be infinitely variable, producing a print exactly matching each individual theatre. Also, if it was intended to counter-balance the effect of the wide-angle lenses, this part of the correction process would have to be made "switch able", in or out, as the "bug- eyed" lenses were normally only used occasionally throughout the early Todd-AO productions. |

|

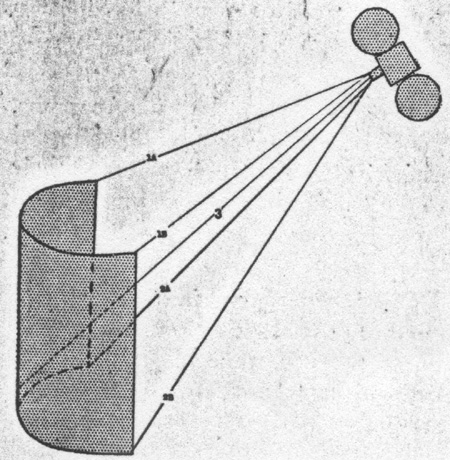

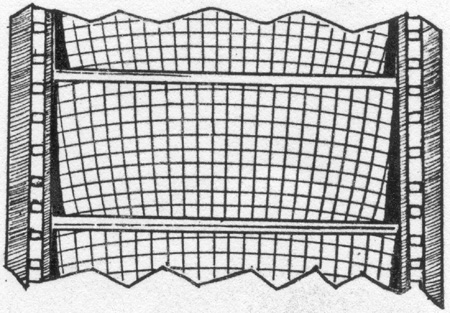

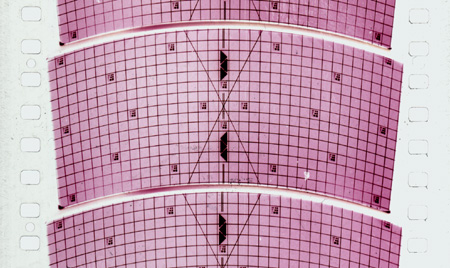

Distortion-Correcting

Print.

Distorting a print in processing so that vertical and

horizontal lines would take the shape shown in the film strip at center

could counter balance this distortion and provide straight lines on the

screen shown at bottom even though that screen be curved. These diagrams

are not meant to be an exact description of the Todd-AO corrective

printing process. Their purpose is to explain in simple language how it

works. In addition to the two types of distortion mentioned above, the

Todd-AO method also corrects a print for distortion caused by the use of

extreme wide-angle lenses in photography. Distortion-Correcting

Print.

Distorting a print in processing so that vertical and

horizontal lines would take the shape shown in the film strip at center

could counter balance this distortion and provide straight lines on the

screen shown at bottom even though that screen be curved. These diagrams

are not meant to be an exact description of the Todd-AO corrective

printing process. Their purpose is to explain in simple language how it

works. In addition to the two types of distortion mentioned above, the

Todd-AO method also corrects a print for distortion caused by the use of

extreme wide-angle lenses in photography.The reason for developing this special printing method was largely financial. After his experiences with the high cost of installing Cinerama, part of Michael Todd's brief to the American Optical Company was to avoid the need for major structural alterations and loss of seating, by using a theatres normal projection room, even if this was in its traditional position high up at back of the balcony. |

|

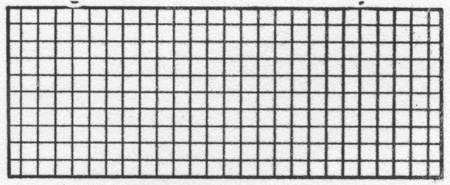

Corrected

Screen Image Corrected

Screen ImageThe American Optical Company continued to pursue the idea, right up to the opening of "Oklahoma!". However, the use of an unsuitable print at the premiere did spoil the screen image, judging by these extracts from contemporary reviews from the New York papers. In fact, further development was abandoned and future Todd-AO installations followed the same pattern of having a new lower projection room constructed, if the rake at the chosen theatre was too steep. It must be remembered that, at the beginning, Todd-AO was regarded as just another process, one among the many system which was constantly being announced. It was the commercial success of "Oklahoma!", followed up by the even greater hits, "Around the World in 80 Days" and "South Pacific" which lead to Todd-AO's acceptance and 70mm projection becoming the cinemas premiere presentation process. |

|

Reviews |

|

|

"......Fortunately, the movie

is true to the original.....and Todd-AO takes the moviegoer out of his

cramped theatre seat and into rolling farmland......The effect is not

completely three-dimensional, but there is a good illusion of depth.....The

figures on the screen are tremendous, and the close-ups are so sharp in

detail that the texture of skin and clothing, the sheen of a girls hair, are

almost real to touch. The colours are vivid, and the movie has many striking

landscapes......But Todd-AO is best in close-ups." TRIBUNE, William K. Zinsser: |

|

|

""Oklahoma!" seems likely to

become as much a box office milestone in movies as it was in stage annals.

The glamour of the title and music should keep the picture in the newly

refurbished Rivoli for months......News about Todd-AO is less

cheery......Level settings run downhill toward the edge of the screen, an

effect that is particularly disconcerting in dance numbers." WORLD TELEGRAM, Altan Cook |

|

The

Todd-AO corrective printing process. The

Todd-AO corrective printing process.This mixed reaction from film critics, together with the general disappointment with the screen image from the first Todd-AO print shown to the public, prompted this report, which appeared in the International Projectionist magazine: "What puzzled some observers was that the picture shown at the Rivoli Theatre had a great many white scratches and distorted horizontal lines. Another print shown privately on the West Coast sometimes earlier was unscratched an nobody had reported distortion. The difference between the New York showing and the earlier test in Hollywood is attributed to the failure of the American Optical Company to produce a good distortion-corrected print in time for the opening. The AO factory in Southbridge, Mass., was badly damaged by flood in August and could not bring the final model of its newly designed printer into use quickly enough. The opening date at the Rivoli could not be postponed. The print used for the premiere, according to Todd-AO president Henry Woodbridge, was a trial product of a crude early version of the printer. It was never meant for exhibition to the public. Since the opening, projection methods at the Rivoli have been changed. Instead of using the theatres regular projection room in the rear of the theatre, which has a very steep angle of throw, an additional booth, built in front of the mezzanine, was put into use. This booth has little or no projection angle, so the corrective print was not required. A contact print, similar to the one shown earlier in Hollywood, was used, and a much better picture resulted. The corrective printing process, developed by Dr O`Brien of the American Optical Company, has not really been tested publicly. This will have to wait until the Company delivers a perfected product" |

|

|

Go:

back

- top

-

back issues Updated 28-07-24 |